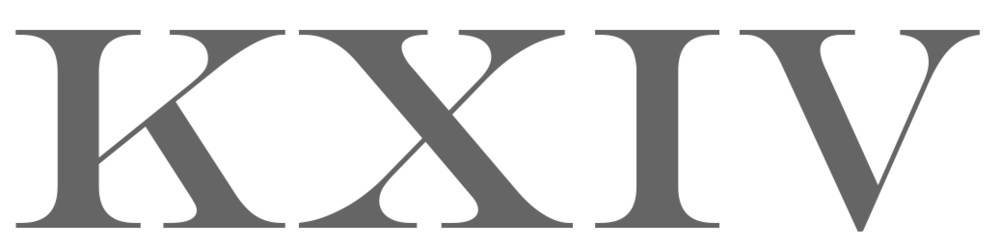

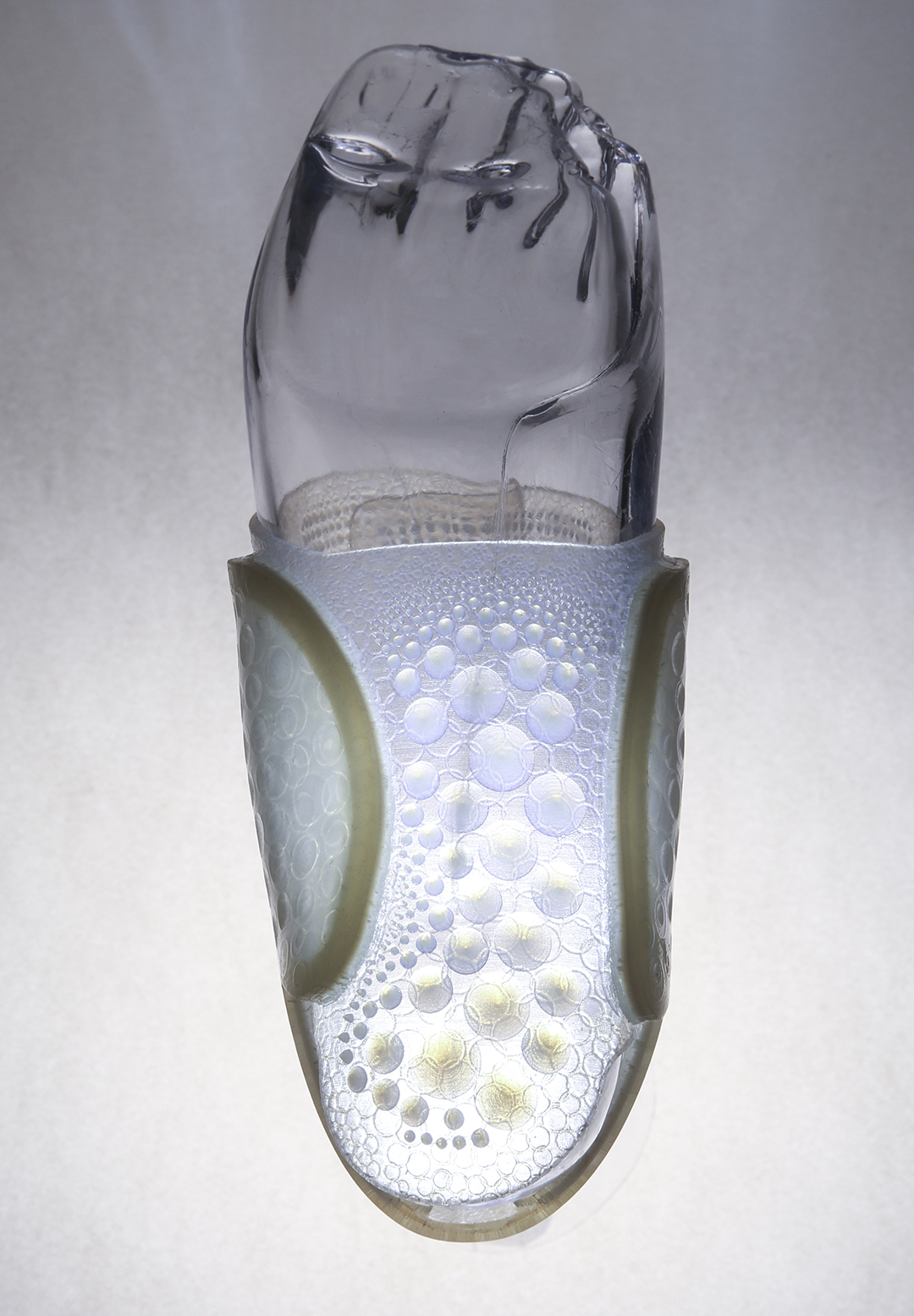

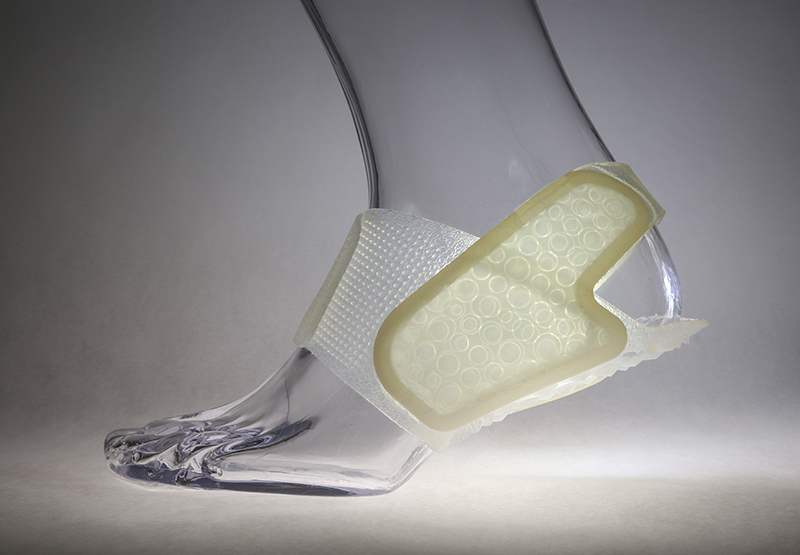

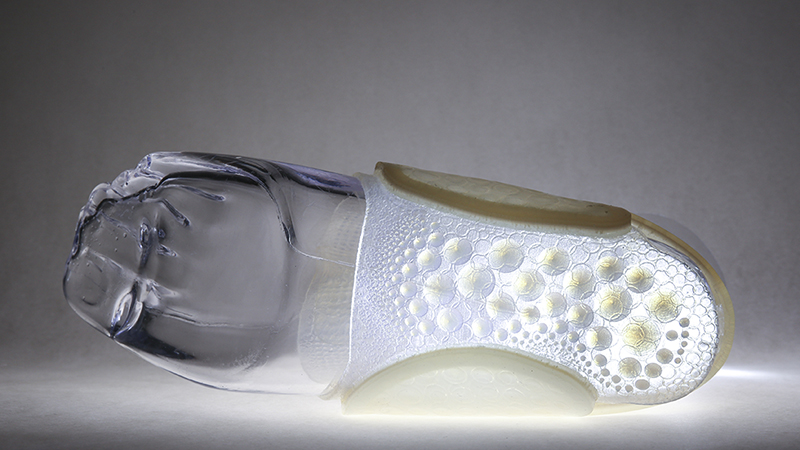

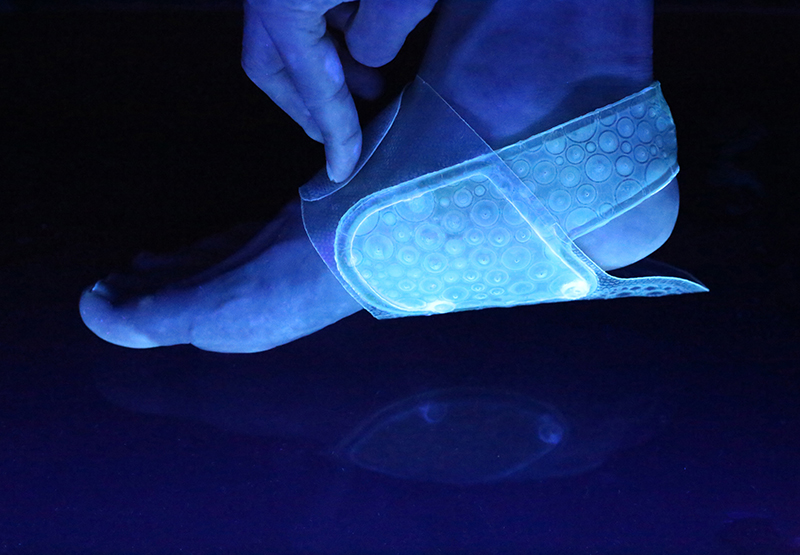

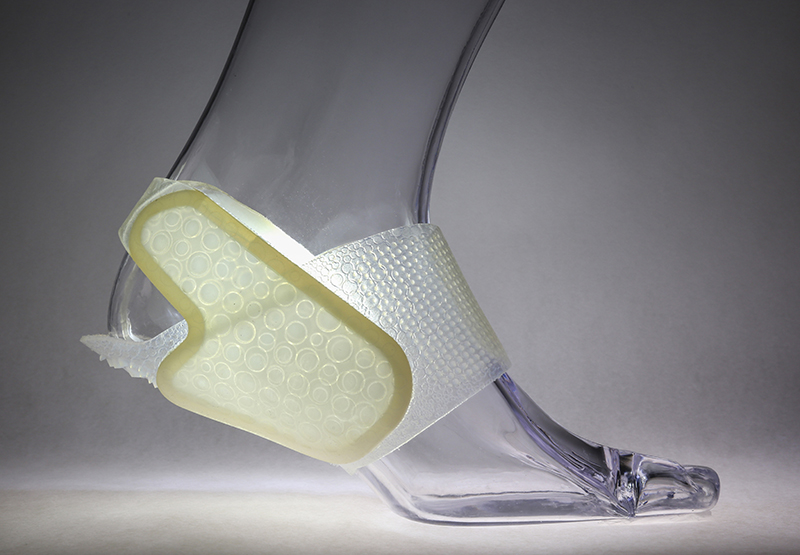

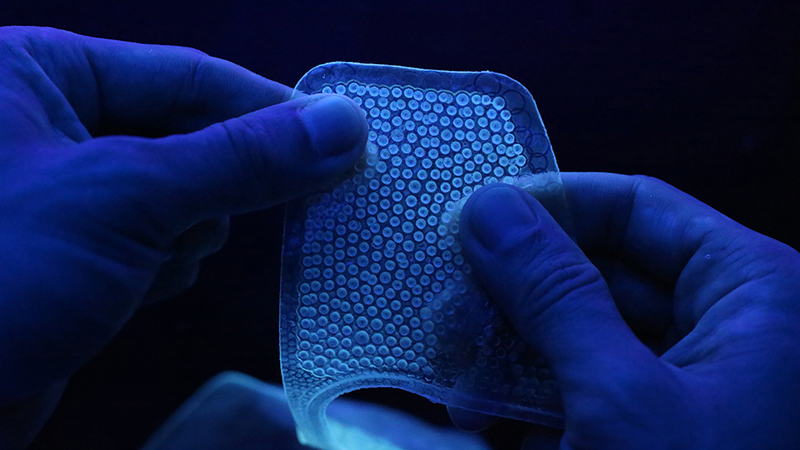

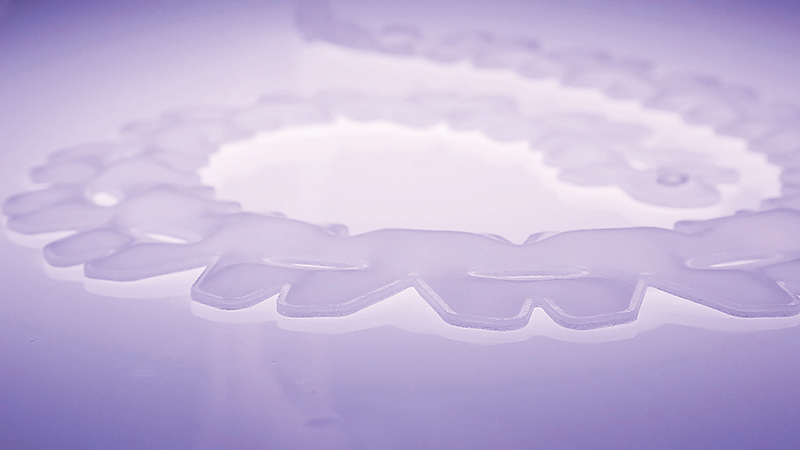

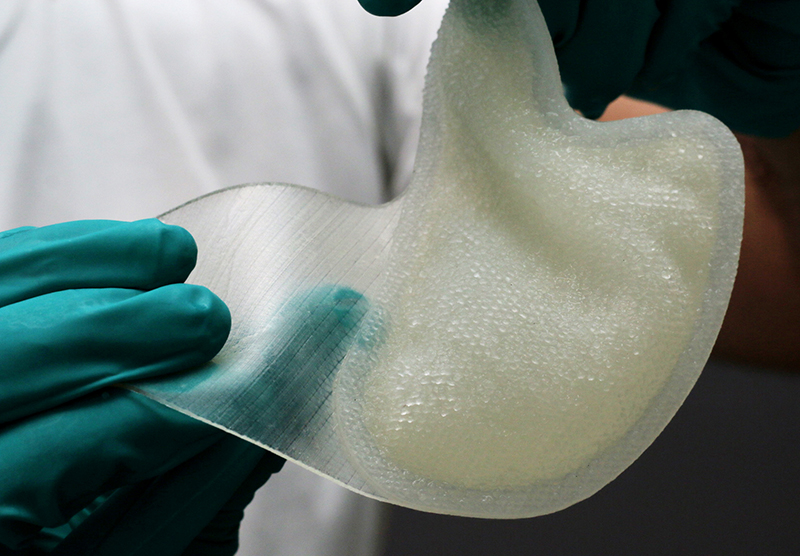

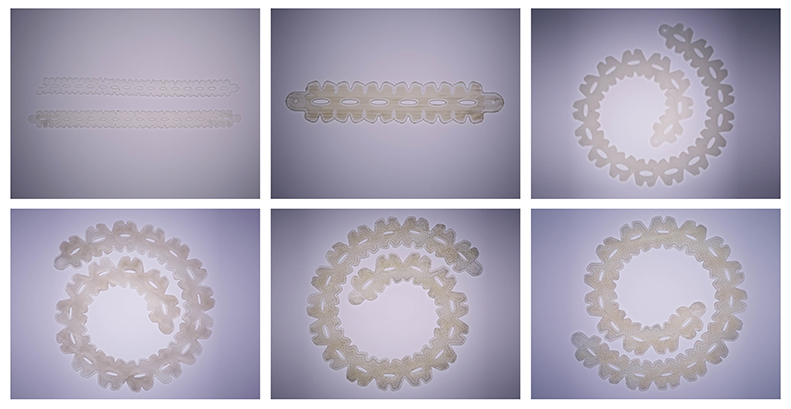

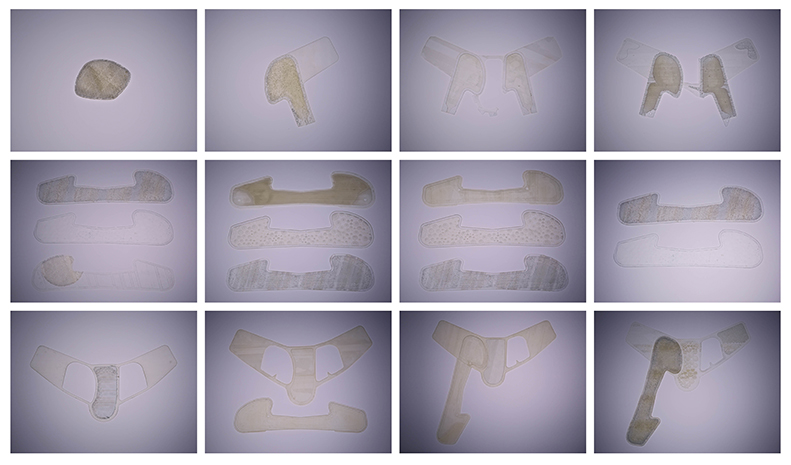

voxel harvest

YEAR:

2018

construction:

Stratasys J750 3D Printer

Team:

Nathan Kiatkulpiboone

Sayjel Patel

collaborators:

Singapore university of technology and design